Project Report: Bio Plant Retrofit and Control System Upgrade

1. Project Overview

This project involved a comprehensive control system upgrade and expansion to support the doubling of the plant’s processing capacity. The works were carried out alongside the installation of two new digesters, seamlessly integrated with the existing facility.

The original plant operated under a legacy control system managing two digesters. To accommodate the expansion and modernize operations, the entire control architecture was redesigned and replaced, while ensuring uninterrupted production throughout the upgrade process.

2. Project Objectives

- Replace the existing legacy control system with a modern, scalable platform.

- Design and manufacture new control panels for the expanded plant infrastructure.

- Develop and implement a unified SCADA system providing centralized control and monitoring.

- Integrate the Alert™ Alarm Management System for enhanced safety and event notification.

- Deliver the full system upgrade without production downtime.

3. Background

The biogas plant’s increased processing capacity required the addition of two new digesters, effectively doubling the overall throughput.

The legacy control system, which managed the existing digesters, lacked the flexibility and performance required for the expanded configuration.

To address this, a complete control system redevelopment was undertaken, ensuring full compatibility between old and new process sections, while maintaining continuous biogas production during the transition.

4. System Design and Engineering

4.1 Control Panel Design and Installation

Custom-built control panels, some exceeding 2 meters in height, were designed and fabricated to manage the expanded plant infrastructure.

Each panel was:

- Fully wired and internally tested before installation.

- Installed and connected to the new section of the plant.

- Verified for electrical integrity and communication readiness prior to integration.

This approach allowed all new components to be commissioned and validated ahead of the final system switchover, minimizing operational disruption.

4.2 Unified Control System

A new, unified control system was developed to seamlessly manage both the existing and newly installed digesters.

This architecture provides integrated process control, ensuring balanced operation, synchronized feeding cycles, and real-time monitoring across all digesters.

5. SCADA System Development

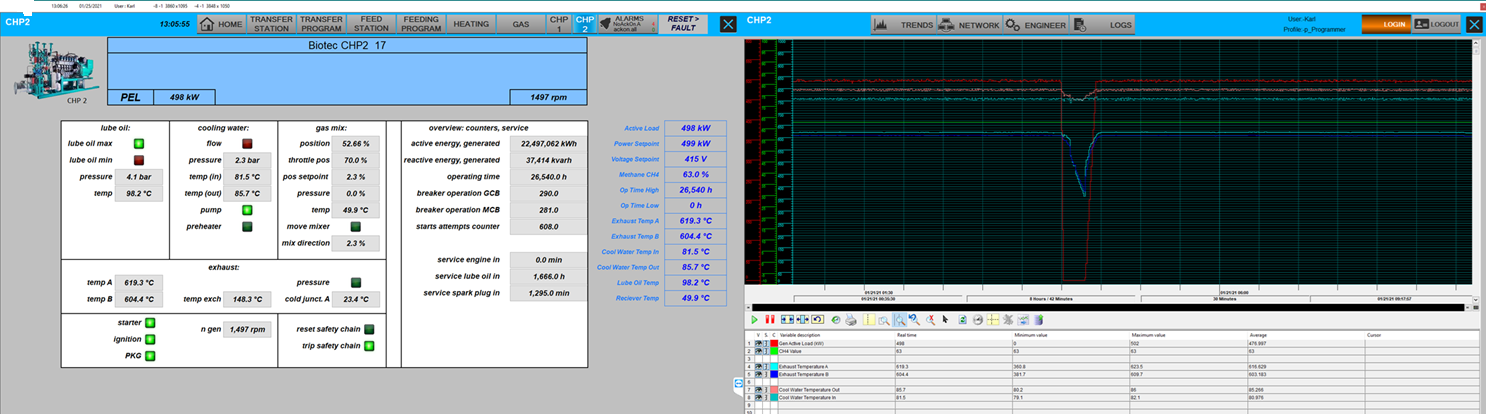

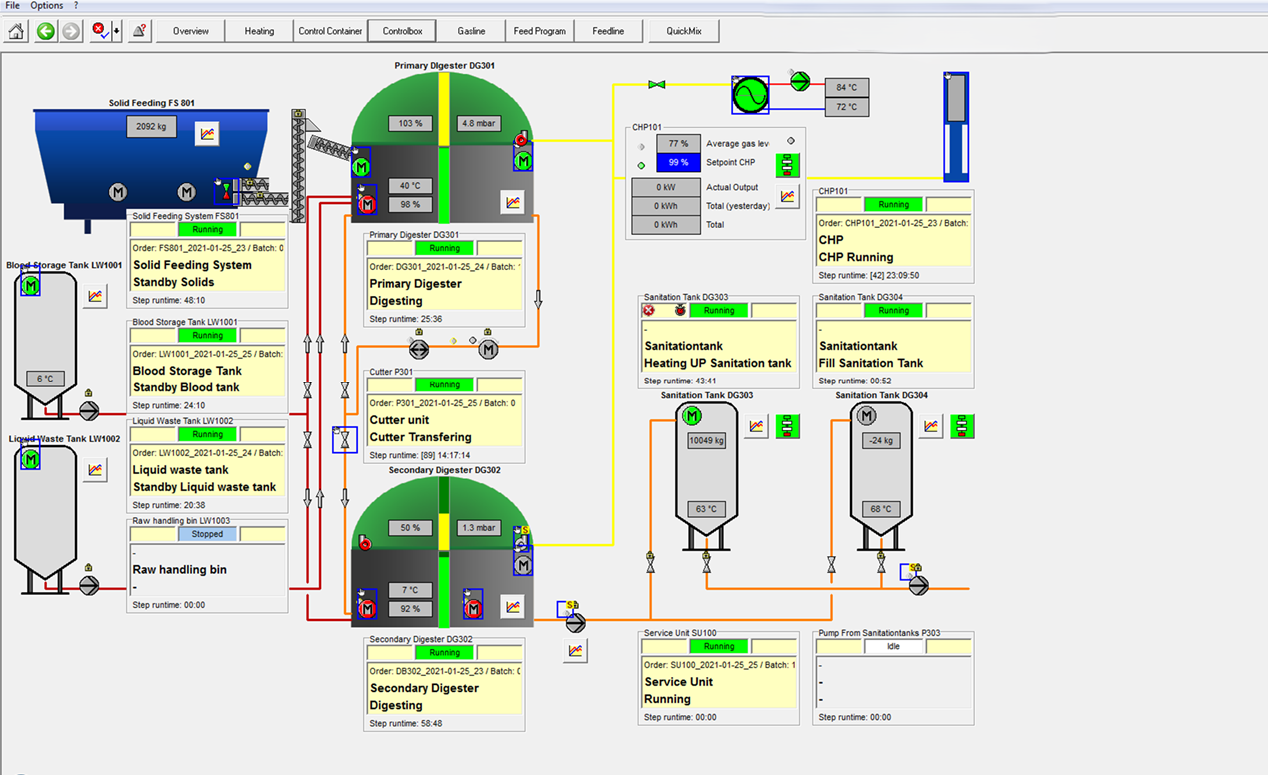

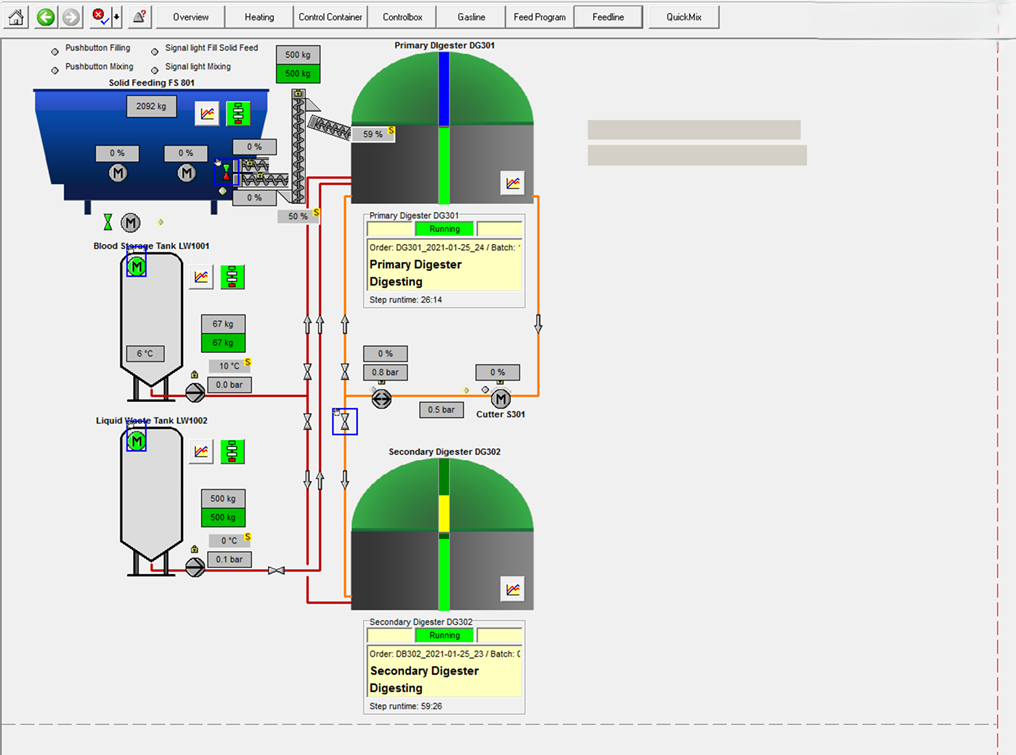

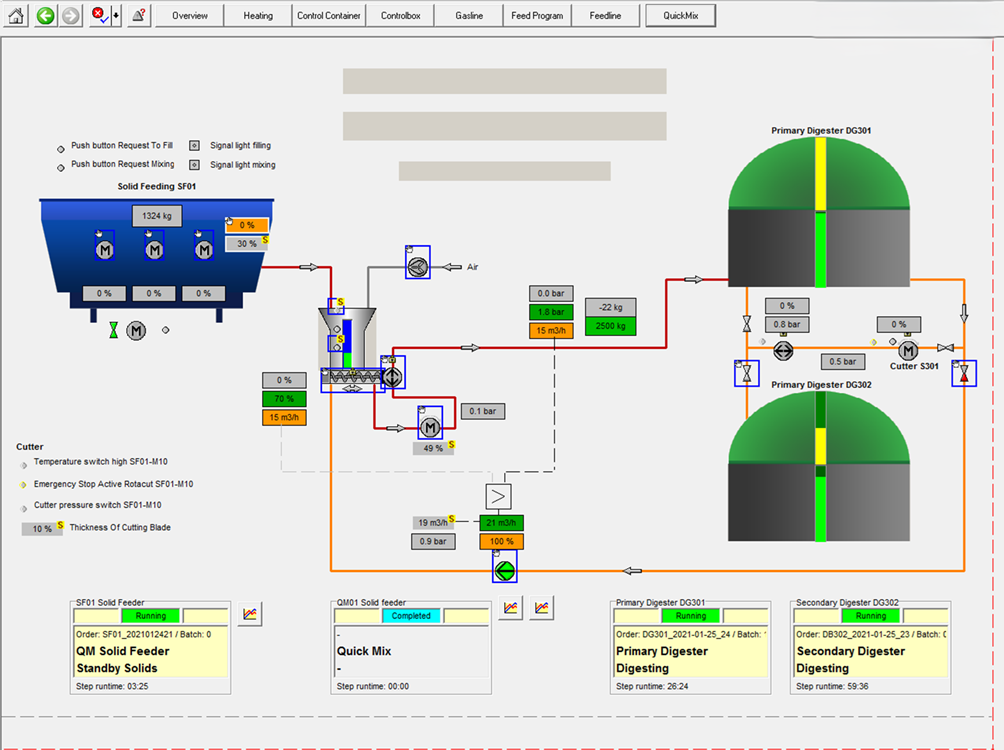

A completely new SCADA (Supervisory Control and Data Acquisition) system was designed and implemented to centralize control and enhance operator visibility.

Key features include:

- Intuitive graphical operator screens with real-time status indicators.

- Comprehensive alarm visualization and historical data logging.

- Full visibility and control across all process areas, including the new digesters.

- Simplified user interface for efficient operation and troubleshooting.

This SCADA environment allows operators to monitor performance, adjust parameters, and manage plant processes with precision and confidence.

6. Alarm Management and Safety Integration

To further improve plant safety and operational responsiveness, the Alert™ Alarm Management System was fully integrated into the new control infrastructure.

This system provides:

- Real-time alarm and event reporting across all process areas.

- Automatic SMS and voice call notifications to operators and maintenance teams.

- Customizable alarm priorities and escalation paths, ensuring timely responses to critical events.

By providing instant notifications and enhanced situational awareness, the system significantly improves both safety and operational reliability.

7. Commissioning and Performance

Comprehensive commissioning and testing were completed following installation and integration.

All systems were verified for control logic accuracy, communication integrity, and functional reliability.

Importantly, the entire project was executed with zero production downtime, demonstrating careful planning, phased commissioning, and effective coordination between installation teams and plant operations.

8. Outcomes and Benefits

The Biogas Plant Control System Upgrade & Expansion successfully delivered a modernized, fully integrated control platform that enhances plant performance, safety, and scalability.

Key outcomes include:

- Unified control architecture for all digesters and process systems.

- Improved operator visibility through the new SCADA interface.

- Increased plant capacity with seamless integration of new digesters.

- Enhanced safety and responsiveness through real-time alarm management.

- Zero production interruption during the entire upgrade process.

9. Conclusion

The successful delivery of this project demonstrates our expertise in complex control system upgrades and live plant integrations.

By maintaining full operational continuity while implementing a complete system replacement, we achieved a significant milestone in operational reliability and process automation excellence.

The new control platform provides a robust foundation for continued growth and optimization of the biogas facility.

Contact Us

Get in touch using the form below.