Project Report: Remote Configuration and SCADA System Development

1. Project Overview

This project involved the remote configuration and development of a new control and SCADA system for a biogas facility.

To streamline the engineering process and minimize site disruption, an EWON remote access system was established, allowing full off-site configuration, testing, and system updates.

Through this setup, our engineering team was able to develop, test, and refine the system software remotely before deployment, significantly improving efficiency and reducing time spent on-site.

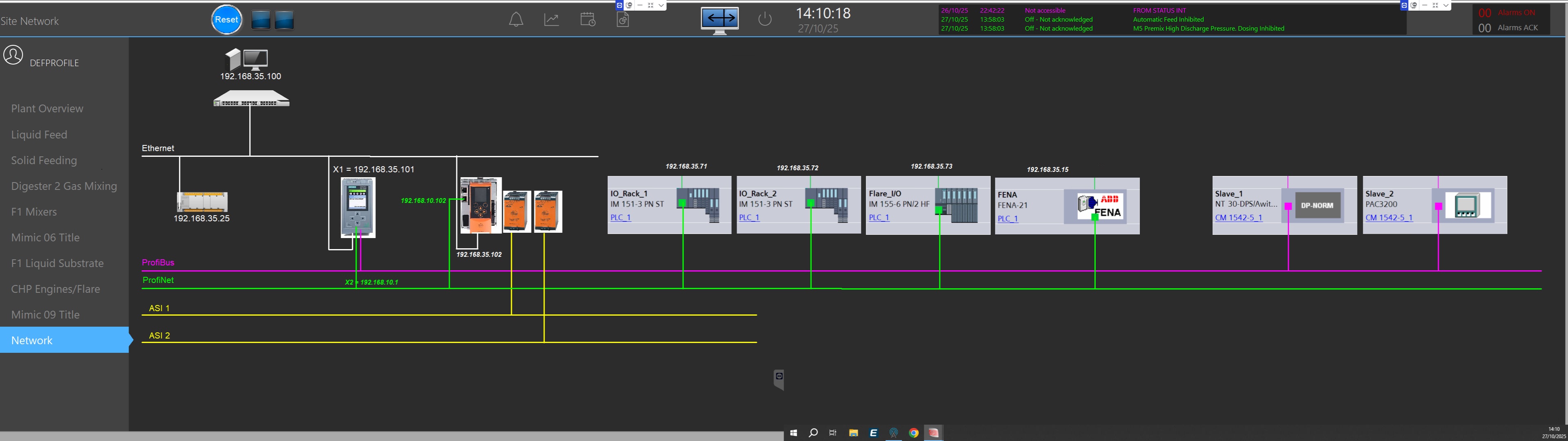

As part of the overall upgrade, the network architecture was segregated into separate Machine Control (MC) and Internet networks to eliminate security vulnerabilities and ensure system integrity.

2. Project Objectives

- Establish an EWON remote access system to enable full off-site configuration and diagnostics.

- Develop and test the new SCADA system remotely using the EWON connection.

- Supply and install a new site PC with all required software packages and licenses preconfigured.

- Implement PcVue SCADA with multiple communication protocols and 5,000 active tags.

- Develop and test PLC software (Rockwell and Siemens) in preparation for site commissioning.

- Provide on-site installation, staff training, and removal of obsolete hardware upon completion.

3. Background

The site’s legacy control infrastructure required engineers to attend in person for even minor configuration changes or diagnostics.

To improve maintainability and reduce operational downtime, an EWON remote connectivity system was installed, allowing secure off-site access for configuration, updates, and troubleshooting.

During this process, the control network was segregated into two distinct layers:

- A Machine Control (MC) network for critical automation and PLC communications.

- An Internet-facing network for remote engineering access and data transfer.

This segregation significantly improved cybersecurity, ensuring that external connectivity could not interfere with or compromise the core control system.

4. System Design and Development

4.1 Remote Engineering Environment

The EWON system provided a secure and reliable connection between the site control network and our engineering office.

This allowed engineers to:

- Access PLCs and SCADA systems remotely for configuration and testing.

- Deploy software updates and patches at scheduled intervals.

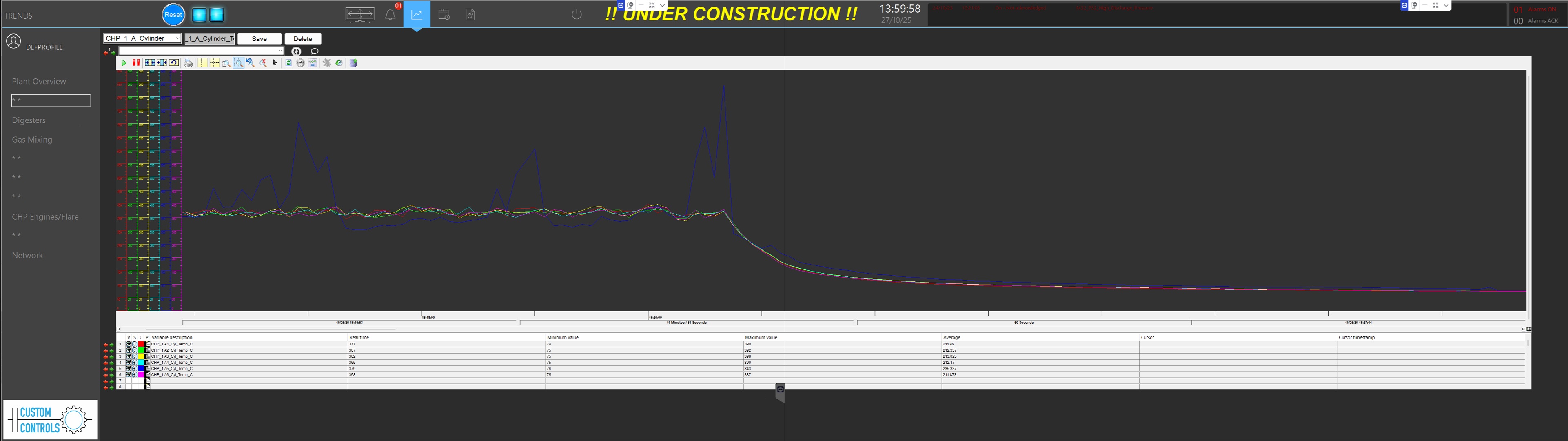

- Troubleshoot and validate system performance in real time.

4.2 SCADA System Configuration

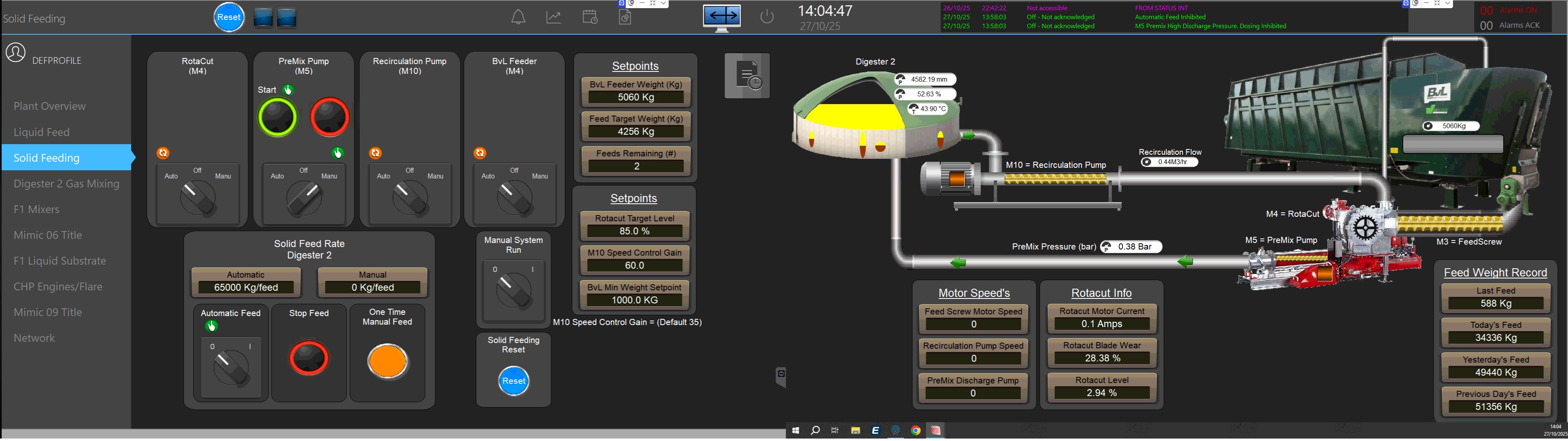

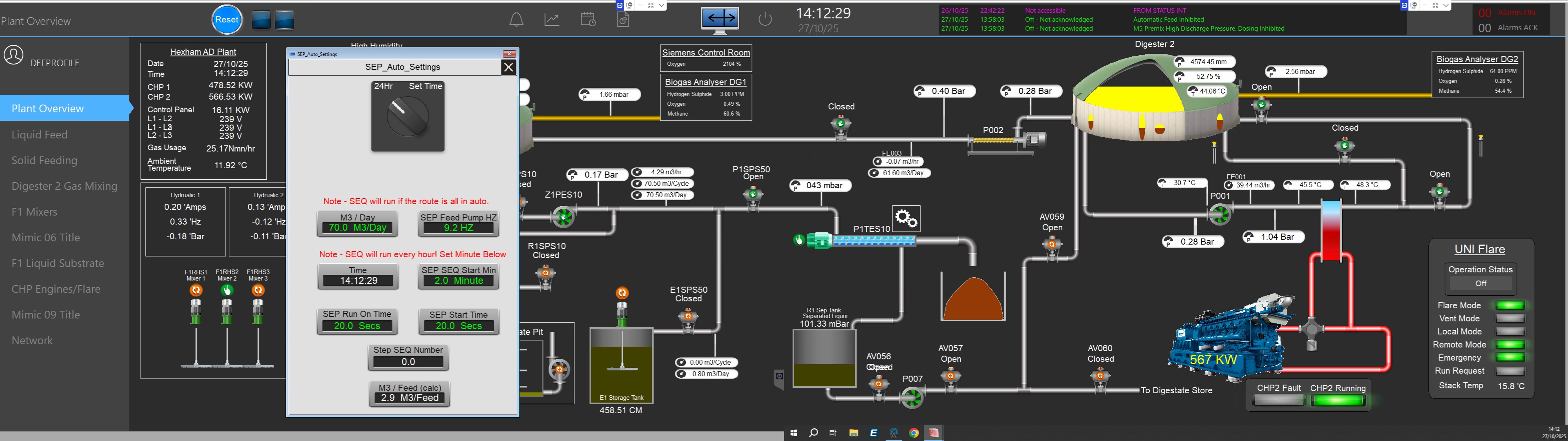

A new PcVue SCADA system was developed and licensed for the biogas plant, including:

- Two communication protocols: Rockwell and Siemens.

- 5,000 process tags for real-time monitoring and control.

- A modular system architecture allowing future scalability.

The SCADA system was first developed and tested off-site, then incrementally downloaded to the new site PC through the EWON network until the final version was completed.

4.3 PLC Software Preparation

In parallel with SCADA development, the PLC software was programmed, simulated, and tested off-site to ensure full compatibility with the upgraded system architecture.

This included:

- Pre-site programming and simulation.

- Full logic testing and validation.

- Preparation for seamless commissioning upon site installation.

5. On-Site Works

Once the remote development phase was complete, our Control Systems Automation Engineer and PLC Programmer attended site to:

- Finalize installation and perform system commissioning.

- Conduct staff training for operators and maintenance personnel.

- Remove obsolete PCs and legacy equipment.

- Verify communication between SCADA, PLCs, and all field devices.

All site activities were completed efficiently, with minimal disruption to plant operations.

6. Outcomes and Benefits

The project successfully delivered a modern, remotely accessible control environment, enabling continuous improvement and simplified system maintenance.

Key outcomes include:

- Remote engineering capability via EWON, reducing travel time and on-site dependency.

- Centralized control and monitoring through the new PcVue SCADA platform.

- Seamless integration of Rockwell and Siemens PLC systems.

- Faster development cycles through off-site testing and staged updates.

- Improved system maintainability and operator training outcomes.

7. Conclusion

The successful implementation of the EWON-based remote engineering environment, combined with the PcVue SCADA platform and network segregation strategy, resulted in a secure, flexible, and efficient control system.

This project demonstrates the effectiveness of combining remote development technologies with robust industrial cybersecurity practices, ensuring both operational reliability and data integrity for the biogas facility.

Contact Us

Get in touch using the form below.